Handcrafted. Untamed. Uncompromised.

At Spark, we don’t cut corners—and we definitely don’t use toxic chemicals to speed things up. While most leather out there is treated with chromium (yeah, that chromium—the one that destroys fibers and lives in toxic waste dumps), we took a different route. We spent years developing a cleaner, better, all-natural tanning process. Partnering with world-class tanneries and master artisans, we created a leather that’s not just beautiful—it’s tough, toxin-free, and built to last decades. We use only full-grain leather—the strongest, most durable part of the hide. The kind that wears in, not out. We specifically source the shoulders of the hide, where the fibers are dense and reliable. Then we slow-tumble them to perfection, giving you a leather that’s soft, pliable, and ready for whatever you throw at it. Forget the marketing fluff—here’s what you really need to know:

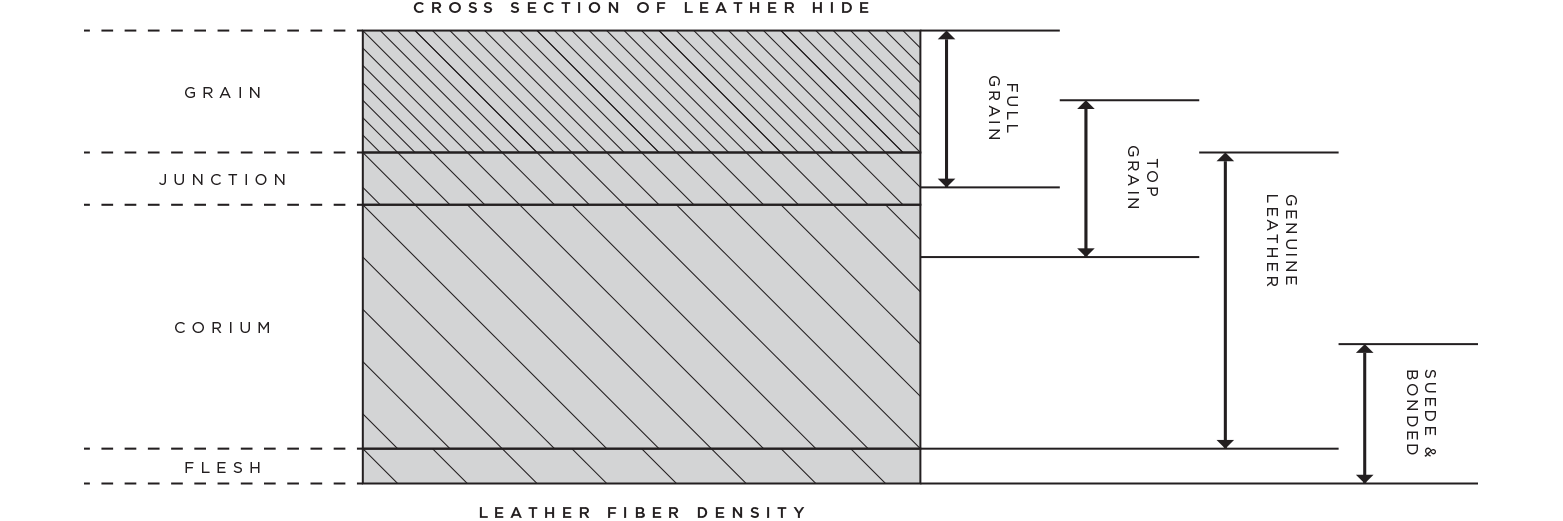

FULL GRAIN

The strongest, rawest, most rugged cut of leather. No sanding, no shortcuts. Just pure, natural hide that ages like whiskey. This is the only leather we use.

TOP GRAIN

Sanded down for a smooth, “perfect” surface. Looks nice, but loses 30% of its strength in the process. Still decent, but not built for the long haul.

GENUINE LEATHER

The trickster of the bunch. Sounds fancy, but it’s mostly scraps and filler, coated in plastic to fake a high-end look. A hard no from us.

SUEDE and BONDED

Ground-up leftovers glued together to look like leather. It’s basically vinyl in disguise. If you’re into gear that falls apart fast, go for it. If not—look elsewhere.

Why It Matters

Great leather isn’t just about looks—it’s about feel, function, and legacy. It should mold to your life, tell your story, and outlast trends, trips, and time itself. When you carry Spark, you’re not just wearing leather—you’re wearing something that was crafted with care, built to outlive you, and made to make a statement.

This isn’t your average leather.

This is Spark Leather—raw, real, and ready for anything.

COLOR AND DYE PROCESS

Spark leather is colored using only natural, vegetable-based dyes. Throughout the coloring process, our leather is tumbled three times. As the leather tumbles, the skin fibers open to allow the natural tannins in the dye to fully penetrate. We color the core first; then we add a base color and a top color to ensure that the color is uniform throughout. This labor of love results in a beautifully-aged patina that looks comfortably worn in but never worn out.

OTHER MATERIALS

We don’t just have high standards for our leather. You can be confident that Spark chooses every material that goes into our bags and accessories with integrity and durability in mind. We complement our uncompromising leather with the best available hardware and materials, such as Gutterman thread, hand-hammered copper rivets, and all-cast metal hardware.

Our canvas is made with organic cotton fiber that has been infused with natural waxes. Compared to traditional waxed canvas, we apply the wax to the canvas as we’re constructing the product, instead of just coating the finished piece. This makes our canvas much more water-resistant and results in a more natural, easy-to-maintain look.